Deer Lodge heavily advertises the tourist attraction of the museum in the old Montana prison, and it is a nice tour to take. We did it a few years ago. This time I got more information on the Chicago, Milwaukee & St. Paul (Milwaukee Road) electric locomotive on display there and we visited the Grant-Kohrs Ranch operated by the National Park Service..

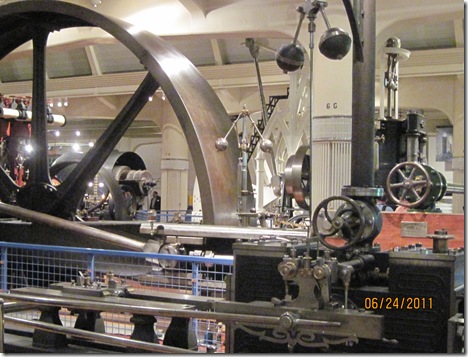

The Milwaukee Road electrified 662 miles of its track in the Northwest; it was the only western road to do so many miles. Some PRR (now AMTRAK) routes in the Northeast have been heavily electrified for years.

This electric locomotive was built by General Electric around 1948 as one of 20 for the Soviet Union. The “Cold War” resulted the locomotives not being delivered. The Milwaukee Road was able to buy 12 of them at bargain prices to use on its previously electrified Rocky Mountain Division headquartered at Deer Lodge MT. This loco, numbered E-70, was the first of the 12 delivered to the road and was used for freight hauling until it ended all electric operations in 1974. The loco ran on 3000 v dc current and was powered by 8 GE 750 motors. In “running order” it weighed over 545,000 lbs. It was cosmetically restored in 1994. It was nicknamed ‘Little Joe” after Joseph Stalin.

When we were in Deer Lodge a few years ago, the impression I got from driving by the ranch was that the historic site would be boring. But after visiting it on this trip, we both thoroughly enjoyed it and recommend it to future visitors. A nice feature of the site is that no admission is charged!

This is the front of the 4000 sq. ft. ranch house built by Johnny Grant in 1862. He operated a trading post on the first floor and the family lived on the second floor He is reported to have had 8 wives (from various Indian tribes) at one time! After four years he became homesick for Canada and returned there, after selling the home and ranch to Conrad Kohrs for $19,200. Mr. Kohrs then ran several butcher shops in the area.

As the Kohrs businesses (ranching, mining, banking and selling water rights) became very profitable, he had the 5,000 sq. ft. brick addition built in 1890. Electricity, central heating and hot and cold running water then were added, with air conditioning! At one time his was the largest cattle ranching operation in Montana, with herds also grazing in Canada, Idaho, Wyoming and Colorado. He truly was a cattle baron.

Oak wainscoting in the dining room of the new addition cost more than a whole home in Deer Lodge! The ceilings in the formal rooms were wallpapered!

Closer view of the set table. All of the furnishings of the first floor of the home are original to the home as last occupied by the Conrad Kohrs family.

New stove in the kitchen with more features than the old! The hood is unique; the heat caught was ducted to heat the second story!

Flower garden next to the house. Vegetable garden near the outbuildings. Fencing on both is to try to keep out the deer.

Rear of chuck wagon, where a docent gave us a cup of cowboy coffee and explained the history of chuck wagons and how they were used on cattle drives and when the cowboys worked on remote parts of the ranch. The cook made Arbuckle coffee and used sourdough, probably for biscuits, in serving the cowboys. I resisted the temptation to tell her of my experiences in cooking with sourdough! How is my facial hair coming?

Beaver Slide Hay Stacker used to build tall hay stacks. Loose hay is pushed by a horse- driven hay fork into a carrier (with the solid floor) at the bottom, and the carrier is pulled up the ramp by horses pulling ropes attached to the carrier. At the top the carrier is tilted to dump the hay into the top of the stack where it is spread and compacted by workers. We watched a good video showing it in use.

Snow-capped peaks add to the views from the ranch. It is a working ranch with 100 head of cattle. The last generation of the Kohrs family to operate the ranch (Conrad Kohrs Warren) sold it to the National Park Service in 1977 to preserve the ranch, its artifacts and extensive financial records from the operation of the ranch by his grandfather and great uncle. Demonstrations are given occasionally of hay cutting using Belgian horses, stacking hay with the beaver stacker, branding cattle and uses of the blacksmith shop.

If you get to Deer Lodge MT be sure to spend a few hours at this great place.